This Website was co-financed by the technical assistance instruments of the Operational Program “Konkurentnost i kohezija” of the European Regional Development Fund. Find out more…

Proton E.E. Electronics was established in 1995 in the city of Daruvar. We started small, with one goal – to provide engineering solutions, sales services and maintenance for local manufacturing factories.

In the year of 2009, we opened our Zagreb office.

Today, things are a bit different but the essence is the same: nowadays, we provide consulting services, engineering services, project management, and programming services. We are also glad that we established very strong connections with our partners and together create a unique ecosystem.

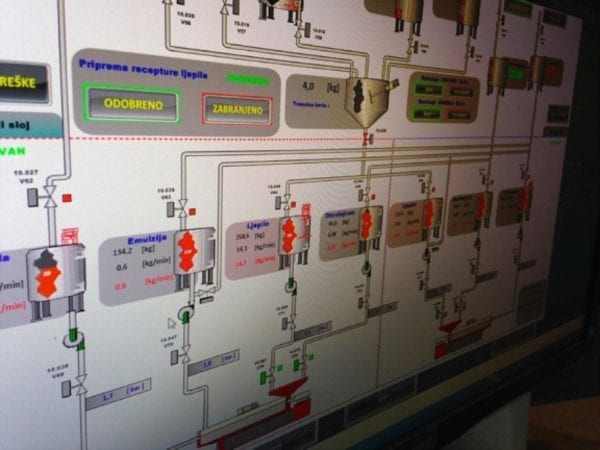

By utilizing software and hardware automation we can see the increase in productivity, safety, and also significant changes when it comes to profitability.

Industry automation is the process of integration of industrial machines for automatic task performing. By doing this, the manufacturing expenses are decreasing, the speed of manufacturing is increased, and entire process is much safer, guaranteeing better product quality.

The system automation improves overall productivity and in exchange, you get efficient time saving, a decrease in production costs and more efficient workflow.

We can adapt the modernization to any type of machine or device, from any manufacturer.

In collaboration with our partners, we offer our clients design, production and commissioning services for machines and production lines.

The industrial market is constantly evolving and changing, which is reflected in a larger selection of machinery and accessories.

The more than 80 models included in the weCat3D series work in accordance with the laser triangulation principle. Two performance classes, 16 selectable measuring ranges and four available laser classes (1, 2M, 3R, 3B), as well as red and blue light sources, provide for maximum diversity in implementing your bin picking application.

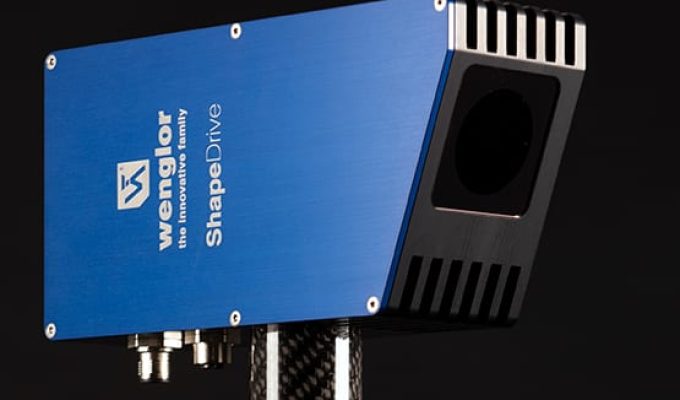

The camera-based 3D sensors included in the ShapeDrive series work in accordance with the structured light principle. All 16 models are equipped with a high-resolution camera with a resolution of 5 or 12 MP. Eight selectable measuring ranges and extensive interfaces permit perfect integration into your system.

Decentralised wireless fieldbus system, compatible with industrial Ethernet, which allows the connection of several slave units to a master unit without having to use cables.

The benefits of SMC’s Wireless Fieldbus System for you:

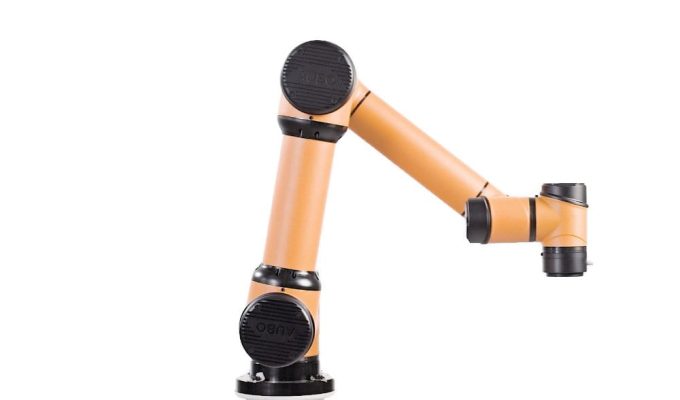

AUBO Robotics AUBO-i10 is a collaborative industrial robot operation with certified safety features, Hand Drive operation, and the power and force limiting robot design type. Certifications include:

The US and Canada certifications are now finalized. 6 axles • 10kg payload • 1350mm capacity

PJ – Duga ulica 12 – Doljani, 43500 Daruvar

Tel. +385 (43) 323 035

Mob. +385 (0)98 377 338

PJ – Krčevina 4 – 10360 Soblinec

Tel. +385 (1) 562 6040

Mob. +385 (0)98 9509 826

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

This website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!

More information about our Privacy policy.