The company's core activities encompass automation, electrical engineering, robotics, and machine manufacturing.

Proton EE-Elektronika LLC’s mission is to deliver top-quality solutions that help clients enhance their production processes.

Through comprehensive operational and logistical support, our goal is to enhance productivity, lower production costs, solve complex problems in the most demanding systems, and make the production process more efficient and secure.

Proton EE-Elektronika LLC was founded in 1995

Electrical design involves the development of project documentation for electrical installations, including:

- creating a process plan

- generating electrical schematics/documentation (ePlan)

- estimating costs.

Following the electrical design, electrical cabinets are constructed, involving:

- cost estimation (selection of suitable components)

- creating an electrical diagram

- designing and assembling electrical cabinets

- installing and testing electrical circuits.

The automation of production processes enhances production efficiency.

Utilizing machines, robots, and computer systems to automate tasks supports human labor, resulting in quicker, more uniform, and more efficient task execution. Automation assumes responsibility for hazardous and physically demanding tasks while also:

- ensuring high precision and consistency

- providing adaptable and easily reconfigurable systems

- improving working conditions for employees

- enhancing competitiveness.

Ensure continuous quality, save resources and improve production.

Industrial robotics is evolving at an astonishing rate, presenting numerous opportunities in manufacturing processes. By leveraging robotics expertise, certain processes or their elements are refined and expedited. Through the development of autonomous or semi-autonomous systems, diverse tasks are executed with minimal human intervention.

Robots can undertake perilous or strenuous tasks, thereby mitigating the risk of injuries or workplace accidents for humans.

Achieve high standards of quality and efficiency in automated manufacturing processes.

Optical inspection utilizes various techniques—high-resolution cameras and other optical sensors—to thoroughly analyse product or material surfaces.

It enables fast, precise, and reliable product or material analysis and plays a key role in ensuring high standards of quality and efficiency in automated manufacturing processes.

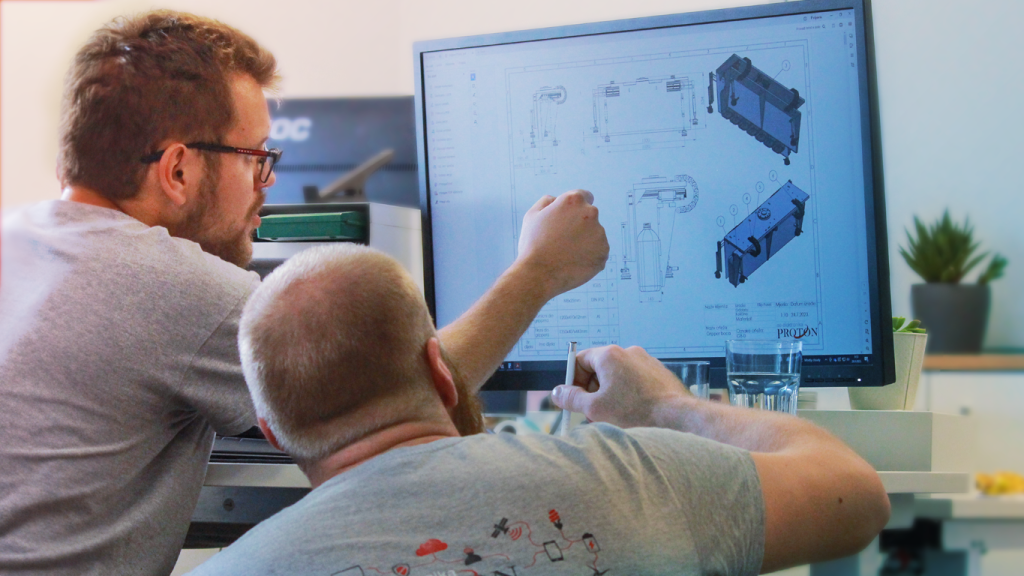

Machine Manufacturing

Special-purpose machines of our own production.

Specialized machines for industrial applications are manufactured at the company’s facility. These machines feature innovative characteristics, adhere to high standards, and consider customer requirements.

We focus on the chemical, food, pharmaceutical, wood, and extractive industries.

Some of the machines in our portfolio include:

- Liquid Filling Line XFR

- Pallet Magazine PAL20S

- Hopper Weigher Machine

- BIG BAG

Join our Team

Our partners are key components of our business strategy. They are innovative companies and organizations that share our passion for progress.

Whether they are small, medium, or large enterprises, our approach is always the same – adapting to individual needs and providing the best solutions.

Discover how our technological solutions can transform your processes and drive your company's growth.

Production of machines for special purposes

Headquarter

Operational office and manufacturing facility

Info mail

Sales