Automation enhances human labour with machines

PLC (Programmable Logic Controller) Programming

PLC programming allows for the control and monitoring of various electrical, pneumatic, hydraulic, and mechanical devices—such as manufacturing machines, conveyor belts, pumps, valves, lighting, HVAC systems, and many other devices used in industry.

The advantages of PLC programming include flexibility, reliability, speed, ease of use and adaptability to different industrial needs.

We offer top-notch PLC programming services for renowned brands (Siemens S1500/S1200, S300, B&R, etc.) on the Codesys platform (Wago, Beckhoff, Berghof, B&R, etc.).

SCADA (Supervisory Control and Data Acquisition) Systems

SCADA systems collect data from various sensors, devices, and controllers and display it on a central computer or graphical interface in real-time.

SCADA system:

- enables monitoring, control, and rapid response,

- alerts operators to deviations or critical conditions,

- analyses data and generates reports,

- is fully secure using authentication, encryption, and other security measures.

Experts at Proton EE-Elektronika develop customized graphical interfaces for monitoring and control on software platforms such as Progea, Wonderware InTouch, and WinCC (TIA Portal), tailored to your processes.

HMI (Human-Machine Interface) systems

HMI systems provide users with an intuitive interface to monitor and control various processes, machines, and systems in manufacturing.

Through an HMI system, it is possible to:

- visually track the operation of industrial processes using graphical displays, diagrams, tables, and alarms,

- interact with various devices and systems—set parameters, start/stop processes, and manage alarms.

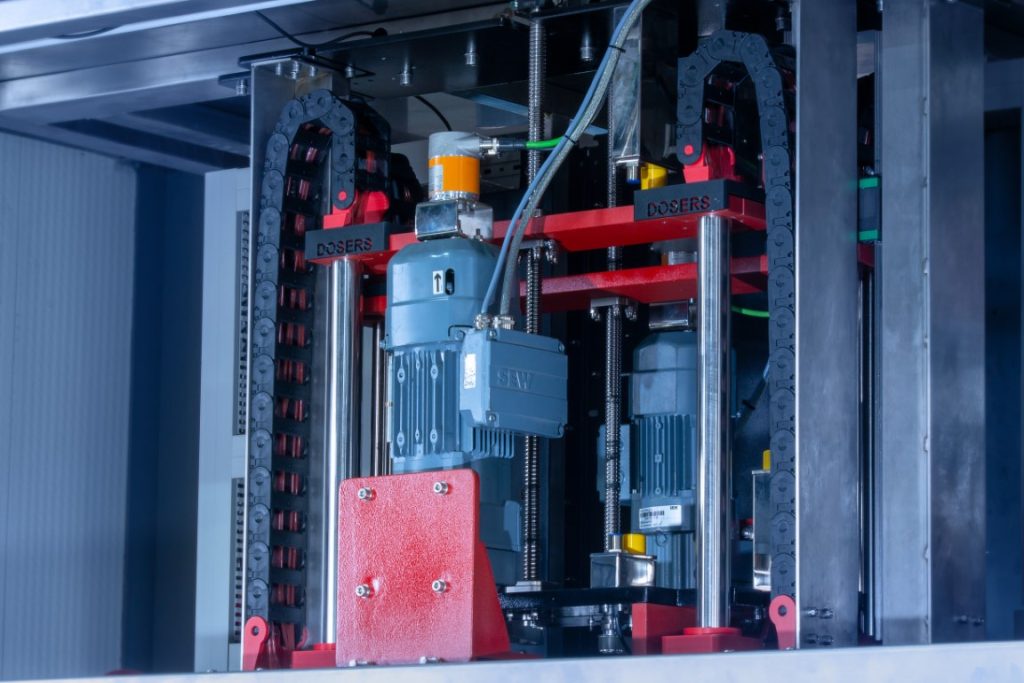

Actuator Control

Actuators perform specific actions based on received instructions or signals. In industry, these include various devices such as valves, motor drives, electric motors, hydraulic and pneumatic actuators, and more.

We have extensive experience in actuator control across various industries including food, pharmaceutical, wood, warehousing, extractive, and bulk materials industries.

- Process technology, PID control

- Servo positioning

- Pneumatic/hydraulic control